Need any help or advice?+44 (0)1782 454499

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

CUSTOMER GALLERY

Buick Stage 2 V6 Carbon / Aramid intake plenum

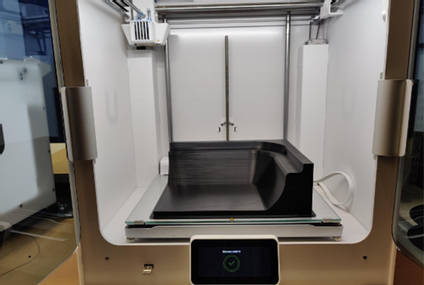

The aim of this project was part of a Bachelor’s thesis to design and manufacture an intake plenum assembly for an ethanol- powered racing engine. This involved a mixture of 3D-printing and fibre reinforced composite materials. Due to the intended use of the vehicle, the aim was to maximize the volumetric efficiency of the engine by studying the theory of intake manifold design and utilizing flow measurements to finish the final product.

The vehicle used in this project was 1987 Buick Regal Turbo-T. Its original 3.8-liter turbocharged V6 engine was replaced with an aftermarket engine based on Buick Motorsport Stage 2 V6 Nascar engine. For a very special racing engine like this it is common that the aftermarket parts needed are not always available. Because of this problem the components for a similar project must usually be manufactured.

Many of the materials were sourced from Easy Composites, including the main carbon twill 210g cloth and also 300g Aramid Cloth. This whole project was 100% Custom, because the intake plenum had to be designed to fit on the top of 80's new old stock Kinsler Magnesium primary pipes, that are designed to suit Buick GTP 4.5L IMSA racing engines.

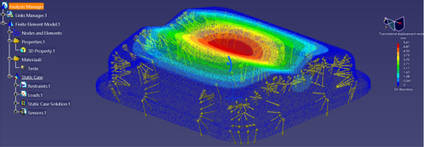

All of the 3D-modelling wad done using Catia V5 CAD Package. The design was also FEM tested to define material thickness for the large un-supported intake plenum lids. Final results showed that the intake will take easily 10 Bar over pressure with the current design. The car will only be running around 1.5 Bar max. boost pressure so should be plenty strong enough.

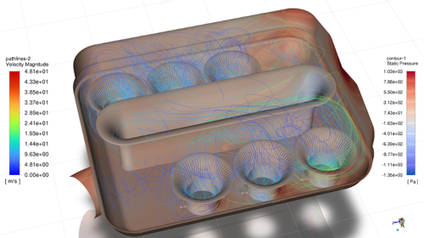

CFD modelling was made with Ansys Fluent before manufacturing anything, so that the design could be improved as much as possible. The main issue with turbocharged engines is uneven air flow to different cylinders. The intake manifold was designed in such a way that the air mass flowing into the engine collides with the top lid of the intake manifold before entering to the cylinders. By breaking the inlet air flow to be as turbulent as possible, based on the simulations, the best possible even flow of air volume between the different cylinders is achieved.

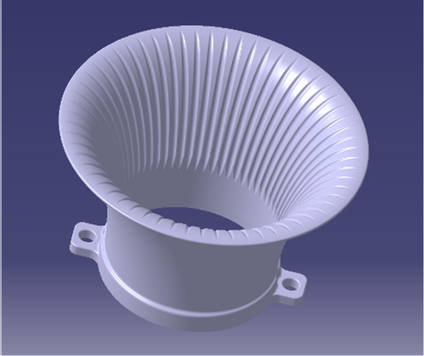

The end result of this Bachelor’s thesis was a lightweight and durable dual plenum intake assembly with adjustable total length. Adjusting the total length of the intake manifold by changing the inlet bell mouths will allow the engine torque properties to be modified to suit specific tracks better. It is easily possible to manufacture more bell mouths, if needed to fine tune those properties. The final intake manifold assembly finishing will be carried out after the new engine block and cylinder heads have been machined to fit together properly.

ABOUT RIKU AITTOKOSKI

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

ABOUT RIKU AITTOKOSKI

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.