Need any help or advice?+44 (0)1782 454499

Downloads (3)

| Safety Datasheet (SDS) - EN | ||

| Safety Datasheet (SDS) - NL | ||

| Technical Datasheet (TDS) |

Specification

Product Data

| Colour | Cream | |

|---|---|---|

| Chemistry / Material | Polyurethane | |

| Viscosity | 50 | mPa.s |

| UV Resistance | Moderate | |

| Brand | Easy Composites | |

| Density | 1.08 | g/cm³ |

Cured Mechanical Properties

| Max Service Temp | 80 | °C |

|---|---|---|

| Hardness | 70 (Hard) | Shore D |

| Flexibility | Hard / Rigid | |

| Tensile Strength | 32 | MPa |

| Flexural Strength | 55 | MPa |

| Flexural Modulus | 1300 | GPa |

| Elongation at Break | 7 | % |

| Tg Onset (DMA) | 80 | °C |

| Linear Shrinkage | 0.2 | % |

| Impact Resistance | 25 | kJ/m2 |

Pot Life and Cure Times

| Pot Life (Typical) | 2 | mins |

|---|---|---|

| Initial Cure Time | 0.33 | Hrs |

General Properties

| Gross Weight | 1.2 | kg |

|---|

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Xencast P2 Fast Cast Polyurethane Casting Resin

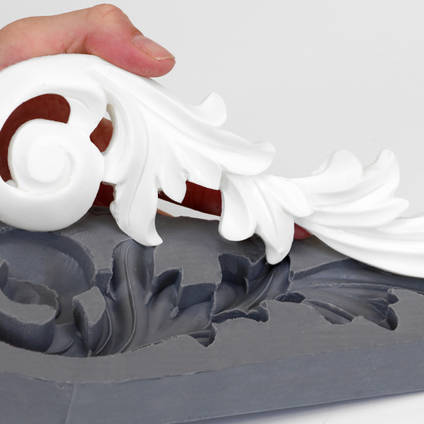

Xencast® P2 is an easy-to-use, cost-effective fast-cast polyurethane (PU) resin system with excellent surface detail and reliability. It is recommended for miniatures, figures, models, patterns, sculptures, prototypes and production parts, in fact resin casting of just about any kind!

P2 cures white or can be pigmented any colour. It typically has a 2-3min pot-life and can be demoulded in 10-20 minutes.

Sold as a kit (Part A and Part B). Available to buy online in 1kg, 2kg, 4kg and 10kg kits.

PRODUCT VERSIONS

Pack Size

AVAILABILITY:More than 10 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Xencast® P2 is an easy-to-use fast-cast polyurethane resin system capable of producing highly detailed castings which can be demoulded within around 10-20 mins. Its unique formulation has been developed to offer the best possible results across a wide range of applications including miniatures, figures, models, patterns, sculptures, prototypes and production parts.

P2 has been formulated for maximum reliability and so requires no degassing and no other specialist equipment. Its low viscosity and modified flow properties result in superior surface detail with minimal air entrapment.

Xencast® P2 pu casting resin is compatible with a wide range of mould materials, fillers, pigments and additives making it the perfect all-purpose casting resin whilst the fast cure time reduces waiting and increases productivity.

Whether you're new to casting or a seasoned professional you're sure to get excellent results with this highly regarded resin system.

Typical Uses

In conjunction with a suitable mould, Xencast® P2 fast cast resin can be used to all manner of cast parts including beautifully detailed figurines, RPG miniatures, models, patterns, prototype parts, foundry patterns, sculptures, fishing lures, ornaments and architectural features.

With the addition of ATH filler powder, Xencast® P2 can also be used to reproduce large sculptures, whereas the addition of metal powders and pigments makes it possible to 'cold cast' bronzes and other authentic-looking metallic castings.

Advantages

- Fine surface detail reproduction with minimal air entrapment

- No degassing necessary

- Fast de-mould time (around 20mins)

- Very easy to use - compatible with most mould materials

- Easily pigmented

- Supports a high ratio of filler

How to Buy

The resin is available in a choice of 1kg, 2kg and 4kg kits, each containing the correct ratios of Part A and Part B.

The 2kg kit is also available as part of the Xencast Resin Casting Starter Kit.

Further Information

Considerations

- Very Short pot-life of just over 2 minutes means you must work quickly

- Not a toughened system so less suitable for more structural applications

Compatibility Information - Dos and Don'ts

Although by no means an exhaustive list, the mould materials, pigments and additives listed below have all been tested and are known to work well with Xencast® P2.

Compatible Moulds

- Condensation/tin cure RTV silicone rubber

- Addition/platinum cure RTV silicone rubber

- Polypropylene and polyethylene mould 'trays'

*for solid moulds such as aluminium tooling, we recommend use of an additional release agent such as PTFE spray or our RW4 Spraywax

Compatible Pigments

- Polyurethane Colour Pigment (for vivid opaque colours)

- Translucent Tinting Pigment (for less vivid opaque colours)

- PearlEx® powder pigments

Compatible Fillers

- All dry filler powders

- All metal powders (for realistic cold castings)

- Photoluminescent (glow in the dark) powders

Xencast® P2 should not be cast into latex rubber moulds. Although P2 has a good moisture tolerance it is still recommended to avoid moulds or substrates which may harbour excessive levels of moisture.

Key Processing Information

- Ease of Use: For hobby or professional use (always follow SDS advice).

- Odour: P2 is almost odourless.

- Safety Precautions: Wear gloves and goggles and work in a well ventilated area. Always read the SDS before use.

- Ambient Conditions: Can be used from 10 to 30°C although pot-life and cure time will be affected significantly. For small or thin-section castings an ambient of 20-25°C is required.

- Degassing: Not necessary. Low viscosity and special flow profile will result in excellent surface finish and minimal air entrapment without degassing.

- Mix Ratio: Mix 'Part A and 'Part B' 1:1 by weight. Use digital scales.

- Mixing: Mix thoroughly by hand for around 1 minutes.

- Pot-Life: 2 mins 15 seconds. Be sure to pour your casting(s) before this time.

- Exotherm (Over-Heating): Resin will heat-up whilst it cures. Large mouldings will require a filler. Once mixed, pour resin immediately.

- Thin Sections: Suitable for fine detail. Minimum section thickness is 0.5mm.

- Maximum Volume: Maximum castable volume for unfilled resin depends on mould shape and material but is approx. 6cm³ in the 'thickest' areas.

- Cure Time/Demould: Larger/thicker castings will heat up more and cure quicker (around 10-15mins). Small castings or thin sections will take longer (around 20mins).

- Pigments and Fillers: A wide range of pigments and fillers (including metal powders) can be added to change the properties and appearance of castings.

- Shelf Life: Minimum shelf life is 12 month under room conditions (18 - 25°C), when stored in original un-opened containers.

Xencast® P2 is an easy-to-use fast-cast polyurethane resin system capable of producing highly detailed castings which can be demoulded within around 10-20 mins. Its unique formulation has been developed to offer the best possible results across a wide range of applications including miniatures, figures, models, patterns, sculptures, prototypes and production parts.

P2 has been formulated for maximum reliability and so requires no degassing and no other specialist equipment. Its low viscosity and modified flow properties result in superior surface detail with minimal air entrapment.

Xencast® P2 pu casting resin is compatible with a wide range of mould materials, fillers, pigments and additives making it the perfect all-purpose casting resin whilst the fast cure time reduces waiting and increases productivity.

Whether you're new to casting or a seasoned professional you're sure to get excellent results with this highly regarded resin system.

Typical Uses

In conjunction with a suitable mould, Xencast® P2 fast cast resin can be used to all manner of cast parts including beautifully detailed figurines, RPG miniatures, models, patterns, prototype parts, foundry patterns, sculptures, fishing lures, ornaments and architectural features.

With the addition of ATH filler powder, Xencast® P2 can also be used to reproduce large sculptures, whereas the addition of metal powders and pigments makes it possible to 'cold cast' bronzes and other authentic-looking metallic castings.

Advantages

- Fine surface detail reproduction with minimal air entrapment

- No degassing necessary

- Fast de-mould time (around 20mins)

- Very easy to use - compatible with most mould materials

- Easily pigmented

- Supports a high ratio of filler

How to Buy

The resin is available in a choice of 1kg, 2kg and 4kg kits, each containing the correct ratios of Part A and Part B.

The 2kg kit is also available as part of the Xencast Resin Casting Starter Kit.

Further Information

Considerations

- Very Short pot-life of just over 2 minutes means you must work quickly

- Not a toughened system so less suitable for more structural applications

Compatibility Information - Dos and Don'ts

Although by no means an exhaustive list, the mould materials, pigments and additives listed below have all been tested and are known to work well with Xencast® P2.

Compatible Moulds

- Condensation/tin cure RTV silicone rubber

- Addition/platinum cure RTV silicone rubber

- Polypropylene and polyethylene mould 'trays'

*for solid moulds such as aluminium tooling, we recommend use of an additional release agent such as PTFE spray or our RW4 Spraywax

Compatible Pigments

- Polyurethane Colour Pigment (for vivid opaque colours)

- Translucent Tinting Pigment (for less vivid opaque colours)

- PearlEx® powder pigments

Compatible Fillers

- All dry filler powders

- All metal powders (for realistic cold castings)

- Photoluminescent (glow in the dark) powders

Xencast® P2 should not be cast into latex rubber moulds. Although P2 has a good moisture tolerance it is still recommended to avoid moulds or substrates which may harbour excessive levels of moisture.

Key Processing Information

- Ease of Use: For hobby or professional use (always follow SDS advice).

- Odour: P2 is almost odourless.

- Safety Precautions: Wear gloves and goggles and work in a well ventilated area. Always read the SDS before use.

- Ambient Conditions: Can be used from 10 to 30°C although pot-life and cure time will be affected significantly. For small or thin-section castings an ambient of 20-25°C is required.

- Degassing: Not necessary. Low viscosity and special flow profile will result in excellent surface finish and minimal air entrapment without degassing.

- Mix Ratio: Mix 'Part A and 'Part B' 1:1 by weight. Use digital scales.

- Mixing: Mix thoroughly by hand for around 1 minutes.

- Pot-Life: 2 mins 15 seconds. Be sure to pour your casting(s) before this time.

- Exotherm (Over-Heating): Resin will heat-up whilst it cures. Large mouldings will require a filler. Once mixed, pour resin immediately.

- Thin Sections: Suitable for fine detail. Minimum section thickness is 0.5mm.

- Maximum Volume: Maximum castable volume for unfilled resin depends on mould shape and material but is approx. 6cm³ in the 'thickest' areas.

- Cure Time/Demould: Larger/thicker castings will heat up more and cure quicker (around 10-15mins). Small castings or thin sections will take longer (around 20mins).

- Pigments and Fillers: A wide range of pigments and fillers (including metal powders) can be added to change the properties and appearance of castings.

- Shelf Life: Minimum shelf life is 12 month under room conditions (18 - 25°C), when stored in original un-opened containers.

Specification

Product Data

| Colour | Cream | |

|---|---|---|

| Chemistry / Material | Polyurethane | |

| Viscosity | 50 | mPa.s |

| UV Resistance | Moderate | |

| Brand | Easy Composites | |

| Density | 1.08 | g/cm³ |

Cured Mechanical Properties

| Max Service Temp | 80 | °C |

|---|---|---|

| Hardness | 70 (Hard) | Shore D |

| Flexibility | Hard / Rigid | |

| Tensile Strength | 32 | MPa |

| Flexural Strength | 55 | MPa |

| Flexural Modulus | 1300 | GPa |

| Elongation at Break | 7 | % |

| Tg Onset (DMA) | 80 | °C |

| Linear Shrinkage | 0.2 | % |

| Impact Resistance | 25 | kJ/m2 |

Pot Life and Cure Times

| Pot Life (Typical) | 2 | mins |

|---|---|---|

| Initial Cure Time | 0.33 | Hrs |

General Properties

| Gross Weight | 1.2 | kg |

|---|

Glass Bubbles can be added to most resins to reduce the density of the cured material. However, bear in mind that they will reduce the clarity of the GlassCast resin, making it more of a translucent 'milky' appearance rather than transparent.

Yes, it would be possible to cast Xencast P2 into an aluminium mould, however, it would be important to use an appropriate release agent on the mould, otherwise the P2 will bond strongly to the aluminium. From our range, Easy-Lease CR1 would NOT be suitable (as it doesn't work effectively for polyurethanes) but waxes like Number 8 Wax or RW4 Spray Wax would be suitable.

The P2 can be painted once fully cured no problem. Sand and clean the surface in accordance with the paint suppliers recommendation and then most modern paints can be applied directly. Some specialist paints may need a standard plastics primer using first for best adhesion.

You would need to do a test with the specific vinyl. Some grades of vinyl may lift or curl when under the resin so doing a test is the safest way to check that your vinyl label will work as intended.

The pigment is made up of mainly pigment powder with a small amount of the polyol Part A which means when adding the pigment, you should always add it to part A, to avoid any reaction occurring.

Due to the fact that only a very small amount of the weight of the pigment is resin (Part A), and pigment pastes are only added at low percentages themselves, it is generally not necessary to adjust the mix ratio of the resin when adding a pigment and so you should mix - for example: (100g resin part A + 5g pigment) with (100g resin part B).

Once fully cured, the P2 FastCast Resin is waterproof and should not be effected by water.

This resin, once allowed to fully cure, can be machined and turned to produce blanks no problem. However the resin is not clear, it cures to an ivory opaque colour. If you need a clear resin for your pen blanks then we would recommend our GlassCast 50 Clear Epoxy Casting Resin which offers great clarity, good machinability and the ability to polish back to a high gloss.

Although inert once fully cured, Xencast P2 has not undergone specific testing and approval for food contact.

Xencast P2 will machine, drill and turn very well once fully cured. In fact, with a sharp knife it can even be carved a little like a very hard wood.

In our experience, the minimum diameter hole we would recommend is 6mm.

Our XenCast P2 Fast Cast cures to a slight off white colour. However if you need a slightly purer white then you can add around 5 percent by weight of our White Polyurethane Pigment to give an improved white finish.

Not if you want them to be actually squishy! The Xencast P2 is great for copying vinyl toys and figures but it does cure to a solid (totally rigid) plastic. If you want the parts you cast to be semi-flexible (like vinyl toys are) then you would need to use our PX90 Hard Rigid Polyurethane Casting Resin.

ASK YOUR OWN QUESTION

Customer Product Reviews for Xencast P2 Fast Cast Polyurethane Casting Resin

everything is great with P2, but it is important to pour fast when ambient temperature is high

Brilliant resin, just what i've been looking for. Don't have to vacuum or compress anymore and increases production capacity due to it's quick demould time.

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.