Need any help or advice?+44 (0)1782 454499

Specification

Weight and Dimensions

| Thickness | 2 | mm |

|---|---|---|

| Width | 1270 | mm |

Product Data

| Max Service Temp | 170 | °C |

|---|---|---|

| Colour | White | |

| Chemistry / Material | Polyester | |

| Brand | Lantor | |

| Density (Dry) | 62.5 | kg/m³ |

Mechanical Properties

| Tensile Strength | 6 | MPa |

|---|---|---|

| Flexural Strength | 16 | MPa |

| Compressive Strength | 4 | MPa |

| Plate Shear Strength | 6 | MPa |

| Plate Shear Modulus | 40 | GPa |

| Density Impregnated | 700 | kg/m3 |

| Flexural Modulus | 1.0 | GPa |

| Resin Uptake | 1 | kg/m² |

General Properties

| Gross Weight | 0.1588 | kg |

|---|

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Lantor Soric SF (1200mm)

- SORIC2

- No reviews

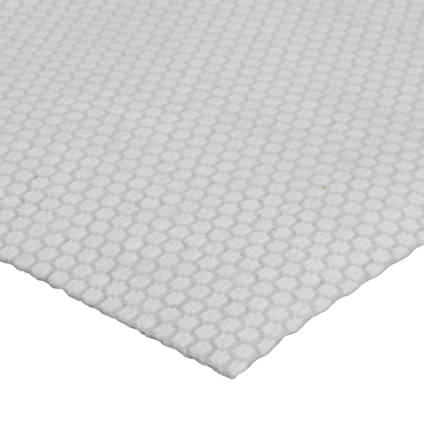

Lantor Soric SF is a very popular core material for resin infused laminates. Soric's honeycomb core structure does not collapse under vacuum and allows resin to flow freely through the material. The core's relatively high resin uptake is offset by its excellent usability, smooth surface finish and high compressive strength make it a great all-rounder, suitable for all but the most critically light-weight applications. Soric is particularly suitable as a core material in resin-infused carbon fibre vehicle panels.

Roll width is 1.2m, sold by the linear metre. Available in 2mm and 3mm thicknesses.

PRODUCT VERSIONS

Thickness

AVAILABILITY:64 in stock available for immediate shipping

Trade discounts

| 0-9 | 10-79 | 80+ |

|---|---|---|

| €12.25 | €11.50 | €9.75 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Soric SF is a special type of pressure stable polyester non-woven core material designed specifically for vacuum resin infusion. Unlike traditional core materials such as coremat, Soric core features pressure stable cells which will not compress under vacuum, maintaining its structure and thickness.

What is more unique about Soric is that it is designed to act as an internal flow media for the infusion, eliminating the need for infusion mesh during the resin infusion process. Its cells are separated by canals through which the resin can easily flow and which, once cured, create a rigid plastic honeycomb which adds considerably to the strength of the finished laminate.

Soric SF can be used to add thickness to any infused laminate including glass, carbon or Kevlar. It is compatible with all resin systems including polyester, vinylester and epoxy (although we always recommend epoxy for high performance composites).

Soric SF has a very low resin uptake and will provide at least a 30% weight saving over solid laminate. The cells have excellent compression and shear strength resulting in a very rigid core. By eliminating the need for infusion mesh and peel ply, the use of Soric SF can reduce layup time, save money on bagging materials and also avoid the waste of resin consumed by the by the peel ply and infusion mesh.

Typical Uses

2mm Soric SF is suitable for use in a huge range of closed mould and resin infusion processes including:

- Marine (hull, decks and superstructures of boats, yachts and larger models)

- Transportation / Motorsport (parts and panels for cars, trailers, trucks, RVs)

- Recreation (kayaks, canoes, surfboards, skimboards)

- Wind Energy (nacelle covers, spinners, enclosures)

How to Buy

Please purchase the number of linear metres you require. When purchasing multiple metres, for lengths under 5 metres, the fabric will be supplied folded to keep package size and hence shipping costs down. If you need your fabric on a roll for a specific application then please contact us and we will be more than happy to supply it that way. For larger lengths, the fabric may be supplied in two or more pieces.

Further Information

How to use Soric SF

When using Soric SF inside a laminate there is no longer any need for an infusion mesh to facilitate resin flow through the reinforcement and therefore also no need for the peel-ply which usually separates the laminate from the mesh.

Traditional Infusion Stack:

Mould Surface | Reinforcement | Peel Ply | Infusion Mesh | Vacuum Bag

Infusion Stack when using Soric SF as Core Material and Internal Flow Media:

Mould Surface | Reinforcement | Soric SF | Reinforcement | Vacuum Bag

Depending on the shape of the mould, resin is generally introduced into one edge of the laminate via infusion spiral. In some situations it may be helpful to position some infusion mesh along the edge of the project to facilitate resin distribution.

As soon as the resin reaches the edge of the laminate it will infuse quickly through the canals in the Soric SF and through the rest of the laminate. The rest of the infusion is undertaken just as normal. Once cured the part can be demoulded and is ready for use.

Advice when infusing without peel-ply

Depending on the type of vacuum bagging film you are using, it might also be necessary to use a release film between the laminate and the vacuum bag to prevent the bag from sticking to the laminate. If using materials from the Easy Composites range you will find that all of our vacuum bagging film is nylon based and as such will not stick to the laminate but for other non-nylon films you may find they will stick and so a release film should be used in such cases.

Trade discounts

| 0-9 | 10-79 | 80+ |

|---|---|---|

| €12.25 | €11.50 | €9.75 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Soric SF is a special type of pressure stable polyester non-woven core material designed specifically for vacuum resin infusion. Unlike traditional core materials such as coremat, Soric core features pressure stable cells which will not compress under vacuum, maintaining its structure and thickness.

What is more unique about Soric is that it is designed to act as an internal flow media for the infusion, eliminating the need for infusion mesh during the resin infusion process. Its cells are separated by canals through which the resin can easily flow and which, once cured, create a rigid plastic honeycomb which adds considerably to the strength of the finished laminate.

Soric SF can be used to add thickness to any infused laminate including glass, carbon or Kevlar. It is compatible with all resin systems including polyester, vinylester and epoxy (although we always recommend epoxy for high performance composites).

Soric SF has a very low resin uptake and will provide at least a 30% weight saving over solid laminate. The cells have excellent compression and shear strength resulting in a very rigid core. By eliminating the need for infusion mesh and peel ply, the use of Soric SF can reduce layup time, save money on bagging materials and also avoid the waste of resin consumed by the by the peel ply and infusion mesh.

Typical Uses

2mm Soric SF is suitable for use in a huge range of closed mould and resin infusion processes including:

- Marine (hull, decks and superstructures of boats, yachts and larger models)

- Transportation / Motorsport (parts and panels for cars, trailers, trucks, RVs)

- Recreation (kayaks, canoes, surfboards, skimboards)

- Wind Energy (nacelle covers, spinners, enclosures)

How to Buy

Please purchase the number of linear metres you require. When purchasing multiple metres, for lengths under 5 metres, the fabric will be supplied folded to keep package size and hence shipping costs down. If you need your fabric on a roll for a specific application then please contact us and we will be more than happy to supply it that way. For larger lengths, the fabric may be supplied in two or more pieces.

Further Information

How to use Soric SF

When using Soric SF inside a laminate there is no longer any need for an infusion mesh to facilitate resin flow through the reinforcement and therefore also no need for the peel-ply which usually separates the laminate from the mesh.

Traditional Infusion Stack:

Mould Surface | Reinforcement | Peel Ply | Infusion Mesh | Vacuum Bag

Infusion Stack when using Soric SF as Core Material and Internal Flow Media:

Mould Surface | Reinforcement | Soric SF | Reinforcement | Vacuum Bag

Depending on the shape of the mould, resin is generally introduced into one edge of the laminate via infusion spiral. In some situations it may be helpful to position some infusion mesh along the edge of the project to facilitate resin distribution.

As soon as the resin reaches the edge of the laminate it will infuse quickly through the canals in the Soric SF and through the rest of the laminate. The rest of the infusion is undertaken just as normal. Once cured the part can be demoulded and is ready for use.

Advice when infusing without peel-ply

Depending on the type of vacuum bagging film you are using, it might also be necessary to use a release film between the laminate and the vacuum bag to prevent the bag from sticking to the laminate. If using materials from the Easy Composites range you will find that all of our vacuum bagging film is nylon based and as such will not stick to the laminate but for other non-nylon films you may find they will stick and so a release film should be used in such cases.

Specification

Weight and Dimensions

| Thickness | 2 | mm |

|---|---|---|

| Width | 1270 | mm |

Product Data

| Max Service Temp | 170 | °C |

|---|---|---|

| Colour | White | |

| Chemistry / Material | Polyester | |

| Brand | Lantor | |

| Density (Dry) | 62.5 | kg/m³ |

Mechanical Properties

| Tensile Strength | 6 | MPa |

|---|---|---|

| Flexural Strength | 16 | MPa |

| Compressive Strength | 4 | MPa |

| Plate Shear Strength | 6 | MPa |

| Plate Shear Modulus | 40 | GPa |

| Density Impregnated | 700 | kg/m3 |

| Flexural Modulus | 1.0 | GPa |

| Resin Uptake | 1 | kg/m² |

General Properties

| Gross Weight | 0.1588 | kg |

|---|

Yes, very much so. In fact, the conformability of Lantor Soric is one of its best features. Really there is no difficulty conforming this core material to even quite complex mould shapes. If necessary it can also be cut and joined.

They're 5mm (nominal)

Yes it is but you'll start to get some innacuracy on the thickness because the texture of the soric sits a bit 'hit-and-miss' when it sits on itself (put simply, sometimes the bumps in it stack up and other times they nest together) so although for certain situations stacking Soric might be fine, if it's a larger area or a whole project that you want more thickness for then I'd probably suggest changing to a core material that's designed to be thickness you're after, such as our 3D|Core which is available in 5mm and 10mm.

Soric can be easily cut using sharp scissors or a sharp knife. Typically when used as a core, it is not physically joined to adjacent pieces. It is sufficient to butt the two pieces against each other.

Yes, very much so. In fact, the conformability of Lantor Soric is one of its best features. Really there is no difficulty conforming this core material to even quite complex mould shapes. If necessary it can also be cut and joined.

They're 5mm (nominal)

Yes it is but you'll start to get some innacuracy on the thickness because the texture of the soric sits a bit 'hit-and-miss' when it sits on itself (put simply, sometimes the bumps in it stack up and other times they nest together) so although for certain situations stacking Soric might be fine, if it's a larger area or a whole project that you want more thickness for then I'd probably suggest changing to a core material that's designed to be thickness you're after, such as our 3D|Core which is available in 5mm and 10mm.

Soric can be easily cut using sharp scissors or a sharp knife. Typically when used as a core, it is not physically joined to adjacent pieces. It is sufficient to butt the two pieces against each other.

If you were just wet-laying then I would suggest that conventional Lantor Coremat would be more suitable but, because you're wet-laying and then vacuum bagging you would find that a conventional Coremat would compress under the vacuum pressure and so in this case, although really intended for infusion, would probably make a better choice.

Soric is so conformation that I wouldn't really say it has a minimum bend radius. The construction of the material is highly conformable, compressible (until wetted out with resin) and non-brittle. You could literally fold it completely back on itself without it breaking and so, if you want to put a number on it, its minimum bend radius would be its own thickness.

This depends on a few factors:

Firstly, exactly which carbon fabric you're using. You will find that closer/tighter weaves are much less prone to showing underlying materials through the gaps in their weave. Plain weave fabrics rarely show what's underneath, as do fabrics with relatively high pick-counts for their tow size, for example our 240g 3k carbon or 650g 12k carbon are both so dense that you can't really see through them. Lower pick-counts for their tow size, such as a 195g 3k or a 400/450g 12k are much more gappy and will show through what's underneath.

Secondly, wow much that fabric is distorted in order to follow the shape of the mould. If you have a highly contoured mould where the fabric will be required to distort quite a lot in order to follow the contours, then it's likely that in places the weave will open up more and be more prone to showing layers underneath.

Finally is how critical you are. We've made lots of parts using single plies of carbon over Soric. If you really scrutinise them then you can usually find the odd spot where you can see a speck or two of the lighter coloured Soric underneath. If cosmetics are the priority then this would be a problem, however, if the alternative is adding in another layer of carbon than you don't need for structural reasons then you need to weigh up the priorities for the component, whether it's cosmetics, or weight. A good compromise would be to use a single ply of a denser fabric, like our 240g 3k carbon cloth; it's slightly more expensive than a 210g but it's considerably cheaper, and lighter, than adding a whole extra ply.

The quoted mechanical data is the Soric impregnated with a typical unsaturated polyester resin.

ASK YOUR OWN QUESTION

Customer Product Reviews for Lantor Soric SF (1200mm)

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

CUSTOMERS ALSO PURCHASED

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.