Hulp of advies nodig?+44 (0)1782 454499

Specificatie

Gewicht en Afmetingen

| Dikte | 6 | mm |

|---|---|---|

| Lengte | 480 | mm |

| Breedte | 480 | mm |

Productgegevens

| Kleur | Zwart | |

|---|---|---|

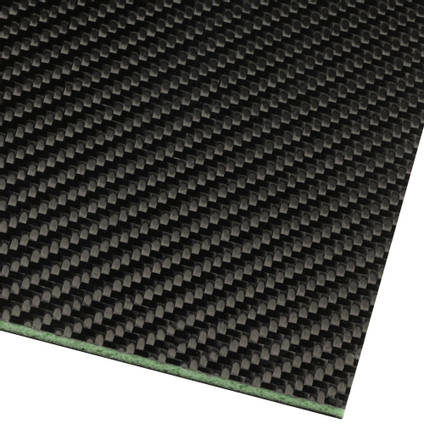

| Uiterlijk | 2x2 Keperbinding (Glanzend) | |

| Type | Enkelzijdig | |

| Harsmatrix | Epoxy |

Specificatie Weefsel

| Vezeloriëntatie | 0, 90 |

|---|

Mechanische Eigenschappen

| Tg Begin (DMA) | 70 | °C |

|---|

Mechanische Eigenschappen na Uitharding

| Trekmodulus bij 0/90° | 6610 | MPa |

|---|---|---|

| Trekmodulus bij 45° | 2060 | MPa |

| Treksterkte bij 0/90° | 71.4 | MPa |

| Treksterkte bij 45° | 36.7 | MPa |

| Rek bij Breuk bij 0/90° | 2.64 | % |

| Rek bij Breuk bij 45° | 24.2 | % |

| Elasticiteitsmodulus bij 0/90 | 9.52 | GPa |

| Druksterkte | 1.33 | MPa |

| Drukmodulus | 72.5 | GPa |

| Kern Schuifsterkte | 1.09 | MPa |

| Kern Schuifmodulus | 27.75 | MPa |

| Kern Thermische Geleidbaarheid bij RT | 0.033 | W/mK |

| Maximale Waterabsorptie | 37.5 | g/m2 |

Algemene eigenschappen

| Brutogewicht | 0.62 | kg |

|---|

Verzendinformatie

Beperkingen

Dit product is niet geclassificeerd als gevaarlijke goederen voor transport en kan zonder beperkingen naar alle bestemmingen worden verzonden.

Verpakkingsgrootte

Er zijn geen beperkingen op de verpakkingsgrootte of toeslagen voor dit product.

Bezorgkosten

Om de bezorgkosten van dit artikel naar uw adres te vinden, voegt u het toe aan uw winkelwagen en gebruikt u vervolgens de directe verzendcalculator op de winkelwagenpagina.

Koolstofvezelpaneel met Schuimkern

- FCP-RI-6-0230

- Geen beoordelingen

Gefabriceerd door Easy Composites in het VK. Premium kwaliteit schuimkern koolstofvezel paneel vervaardigd met behulp van 100% high-strength koolstof weefsel aan weerszijden van een structureel kernmateriaal met lage dichtheid. Deze panelen hebben een gladde, glanzende, cosmetische kwaliteit koolstofvezel afwerking aan één zijde en een gladde, satijnen koolstofvezel afwerking aan de achterkant.

Deze hoogwaardige panelen zijn ontworpen om maximale stijfheid te bieden bij een minimaal gewicht en zijn ideaal voor een reeks toepassingen, waaronder motorsport, scheepvaart, winkelinrichting, tentoonstellingen, automatisering, medische, wetenschappelijke en meer.

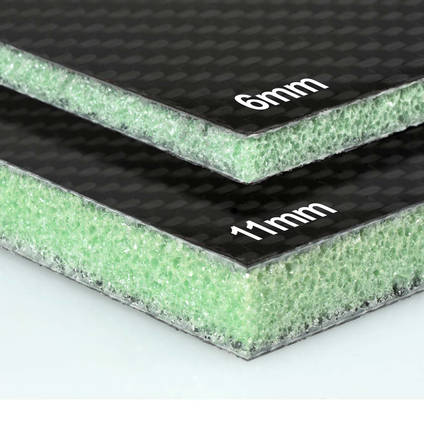

Verkrijgbaar in diktes van 6mm, 11mm in een reeks plaatformaten tot 2m².

PRODUCTVERSIES

Plaatgrootte

Dikte

BESCHIKBAARHEID:2 op voorraad beschikbaar voor onmiddellijke verzending

Korting voor de handel

| 0-4 | 5-9 | 10-19 | 20+ |

|---|---|---|---|

| €57.75 | €54.75 | €52.00 | €49.00 |

Wij zijn niet te verslaan op prijs!

Als u denkt dat u elders een gelijkwaardig product goedkoper kunt kopen, neem dan contact met ons op om uw wensen te bespreken.

Onze Hoge Sterkte Koolstofvezel Foam Core Panel, vervaardigd bij Easy Composites in het Verenigd Koninkrijk met behulp van geavanceerde technologie, bereikt de ultieme combinatie van sterkte, licht gewicht en een verbluffend uiterlijk, waardoor het paneel ideaal is voor een breed scala aan toepassingen, van structurele engineering toepassingen tot tentoonstellingssystemen en architectonisch gebruik.

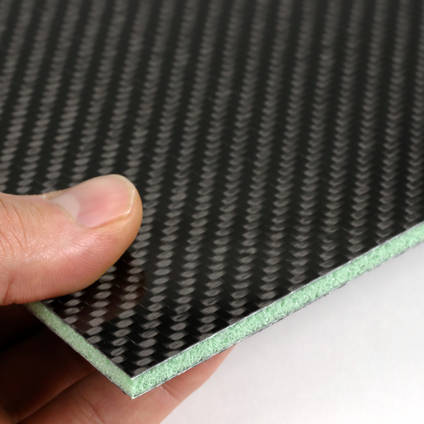

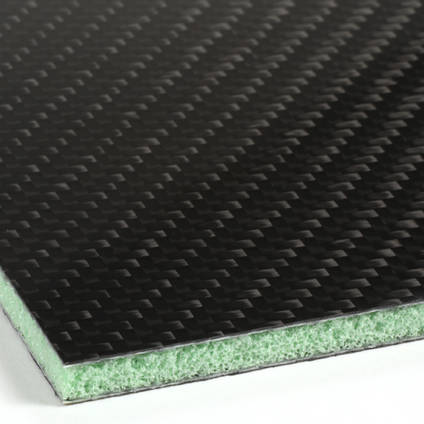

Dit speciaal ontwikkelde koolstofvezelpaneel met schuimkern is verkrijgbaar in diktes van 6mm en 11mm en is vervaardigd met behulp van een combinatie van echte, zeer sterke 2/2 keperbinding 3k koolstofvezel gecombineerd met een laag geweven E-glas aan weerszijden van een lichtgewicht gesloten cel PVC-schuimkern om een lichtgewicht paneel met uitstekende buigsterkte te creëren.

Voor een maximale sterkte-gewichtsverhouding worden de platen vervaardigd zonder gelcoat of oppervlaktecoating, maar onze eigen hars technologie zorgt voor een glanzend, porievrij 'klasse-A' oppervlak op de cosmetische zijde.

De harsmatrix is overal epoxy met een hoge temperatuur nabehandeling voor maximale mechanische prestaties.

Uiterlijk

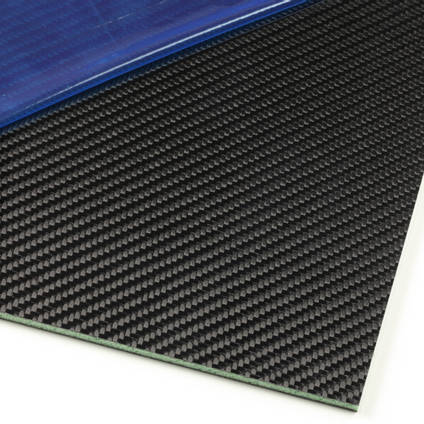

De cosmetische 'A'-zijde van het paneel heeft een hoogglans koolstofvezelafwerking, beschermd door een verwijderbare blauwe beschermfolie.

De achterkant is een gladde, satijnen koolstofvezelafwerking, maar is niet bedoeld als cosmetische zijde en als zodanig zijn enkele visuele imperfecties of lichte krassen van het persen, hanteren en snijden te verwachten. Opmerking: we voegen vaak ook een blauwe film toe aan de achterkant van de plaat, alleen om krassen door hantering te minimaliseren, maar dit geeft niet aan dat de achterkant ('B'-zijde) bedoeld is als cosmetische afwerking.

Typische Toepassingen

Verkrijgbaar in plaatformaten tot 2000mm x 980mm in diktes van 6mm en 11mm, deze zeer sterke koolstofvezel panelen zijn geschikt voor een breed scala aan projecten:

- Lichtgewicht Structurele/Engineering Projecten

- Voertuigpanelen / Bodemplaten

- Koolstofvezel Splitters

- Scheepvaartpanelen

- Tentoonstellingssystemen / Displays

- Architectonisch Gebruik

Voordelen

Door gebruik te maken van een schuimkern kunnen we een paneel met maximale stijfheid realiseren bij een minimaal mogelijk gewicht. Conventionele 'massieve' koolstofvezelplaten, gemaakt zonder kernmateriaal, zijn aanzienlijk zwaarder voor dezelfde buigsterkte. De maattolerantie op lengte en breedte is doorgaans + - 2.5mm.

Typische Toepassingen

Snijden, Vormen & Afwerken

Zoals met alle koolstofvezel en composieten (zoals glasvezel, carbon Kevlar etc.) kunnen goede resultaten worden bereikt voor het snijden, vormen en afwerken van deze plaat met behulp van regulier werkplaatsgereedschap zoals metaalzagen, decoupeerzagen en schuurpapier. Gespecialiseerd gereedschap kan het werk echter verlichten en betere resultaten opleveren.

Wij adviseren Perma-Grit Gereedschap voor het snijden en vormen van onze koolstofvezelplaten.

Korting voor de handel

| 0-4 | 5-9 | 10-19 | 20+ |

|---|---|---|---|

| €57.75 | €54.75 | €52.00 | €49.00 |

Wij zijn niet te verslaan op prijs!

Als u denkt dat u elders een gelijkwaardig product goedkoper kunt kopen, neem dan contact met ons op om uw wensen te bespreken.

Onze Hoge Sterkte Koolstofvezel Foam Core Panel, vervaardigd bij Easy Composites in het Verenigd Koninkrijk met behulp van geavanceerde technologie, bereikt de ultieme combinatie van sterkte, licht gewicht en een verbluffend uiterlijk, waardoor het paneel ideaal is voor een breed scala aan toepassingen, van structurele engineering toepassingen tot tentoonstellingssystemen en architectonisch gebruik.

Dit speciaal ontwikkelde koolstofvezelpaneel met schuimkern is verkrijgbaar in diktes van 6mm en 11mm en is vervaardigd met behulp van een combinatie van echte, zeer sterke 2/2 keperbinding 3k koolstofvezel gecombineerd met een laag geweven E-glas aan weerszijden van een lichtgewicht gesloten cel PVC-schuimkern om een lichtgewicht paneel met uitstekende buigsterkte te creëren.

Voor een maximale sterkte-gewichtsverhouding worden de platen vervaardigd zonder gelcoat of oppervlaktecoating, maar onze eigen hars technologie zorgt voor een glanzend, porievrij 'klasse-A' oppervlak op de cosmetische zijde.

De harsmatrix is overal epoxy met een hoge temperatuur nabehandeling voor maximale mechanische prestaties.

Uiterlijk

De cosmetische 'A'-zijde van het paneel heeft een hoogglans koolstofvezelafwerking, beschermd door een verwijderbare blauwe beschermfolie.

De achterkant is een gladde, satijnen koolstofvezelafwerking, maar is niet bedoeld als cosmetische zijde en als zodanig zijn enkele visuele imperfecties of lichte krassen van het persen, hanteren en snijden te verwachten. Opmerking: we voegen vaak ook een blauwe film toe aan de achterkant van de plaat, alleen om krassen door hantering te minimaliseren, maar dit geeft niet aan dat de achterkant ('B'-zijde) bedoeld is als cosmetische afwerking.

Typische Toepassingen

Verkrijgbaar in plaatformaten tot 2000mm x 980mm in diktes van 6mm en 11mm, deze zeer sterke koolstofvezel panelen zijn geschikt voor een breed scala aan projecten:

- Lichtgewicht Structurele/Engineering Projecten

- Voertuigpanelen / Bodemplaten

- Koolstofvezel Splitters

- Scheepvaartpanelen

- Tentoonstellingssystemen / Displays

- Architectonisch Gebruik

Voordelen

Door gebruik te maken van een schuimkern kunnen we een paneel met maximale stijfheid realiseren bij een minimaal mogelijk gewicht. Conventionele 'massieve' koolstofvezelplaten, gemaakt zonder kernmateriaal, zijn aanzienlijk zwaarder voor dezelfde buigsterkte. De maattolerantie op lengte en breedte is doorgaans + - 2.5mm.

Typische Toepassingen

Cutting, Shaping & Finishing

Zoals met alle koolstofvezel en composieten (zoals glasvezel, carbon Kevlar etc.) kunnen goede resultaten worden bereikt voor het snijden, vormen en afwerken van deze plaat met behulp van regulier werkplaatsgereedschap zoals metaalzagen, decoupeerzagen en schuurpapier. Gespecialiseerd gereedschap kan het werk echter verlichten en betere resultaten opleveren.

Wij adviseren Perma-Grit Gereedschap voor het snijden en vormen van onze koolstofvezelplaten.

Specificatie

Gewicht en Afmetingen

| Dikte | 6 | mm |

|---|---|---|

| Lengte | 480 | mm |

| Breedte | 480 | mm |

Productgegevens

| Kleur | Zwart | |

|---|---|---|

| Uiterlijk | 2x2 Keperbinding (Glanzend) | |

| Type | Enkelzijdig | |

| Harsmatrix | Epoxy |

Specificatie Weefsel

| Vezeloriëntatie | 0, 90 |

|---|

Mechanische Eigenschappen

| Tg Begin (DMA) | 70 | °C |

|---|

Mechanische Eigenschappen na Uitharding

| Trekmodulus bij 0/90° | 6610 | MPa |

|---|---|---|

| Trekmodulus bij 45° | 2060 | MPa |

| Treksterkte bij 0/90° | 71.4 | MPa |

| Treksterkte bij 45° | 36.7 | MPa |

| Rek bij Breuk bij 0/90° | 2.64 | % |

| Rek bij Breuk bij 45° | 24.2 | % |

| Elasticiteitsmodulus bij 0/90 | 9.52 | GPa |

| Druksterkte | 1.33 | MPa |

| Drukmodulus | 72.5 | GPa |

| Kern Schuifsterkte | 1.09 | MPa |

| Kern Schuifmodulus | 27.75 | MPa |

| Kern Thermische Geleidbaarheid bij RT | 0.033 | W/mK |

| Maximale Waterabsorptie | 37.5 | g/m2 |

Algemene eigenschappen

| Brutogewicht | 0.62 | kg |

|---|

Of het afdichten van snijranden zinvol is, hangt echt af van de toepassing en de omgeving waarin de plaat wordt gebruikt. We hebben het dan vooral over langdurige of permanente blootstelling aan vloeistoffen zoals water, chemicaliën, olie, enz. In een toepassing waarbij de snijrand van de plaat regelmatig of permanent wordt blootgesteld aan vloeistoffen, is het zinvol om de rand af te dichten om te voorkomen dat er water binnendringt. Na verloop van tijd kan dit water zich via de vezels verplaatsen en delaminatie veroorzaken.

Op basis van het bovenstaande, als randsealing als voordelig wordt beschouwd, kan dit het beste worden gedaan met behulp van een epoxyhars die moet worden gemengd (volgens de bijbehorende instructies) en op de snijrand moet worden geborsteld of gesmeerd, of de snijrand erin moet worden gedoopt. Hoewel het zeker niet essentieel is, zou een bijzonder geschikte hars onze XCR Epoxy Coating Resin zijn.

Het is niet mogelijk om een exact gewicht te geven, omdat dit afhangt van veel factoren (hoe de plaat wordt ondersteund, wat de overspanning is, hoe het gewicht wordt geladen, of de plaat een 'vrije overspanning' is (d.w.z. niet gebonden/vast) of gebonden of vast (zodat u een 'trommelvel'-effect krijgt). Dat gezegd hebbende, kunt u er zeker van zijn dat een plaat die over een gat is geschoven, zodanig dat de plaat aan alle kanten wordt ondersteund, gemakkelijk het gewicht van een gemiddeld persoon kan dragen.

Het schuim dat in deze plaat wordt gebruikt, is onze EasyCell 75, waarvan het gegevensblad hier beschikbaar is: EasyCell 75. We hebben momenteel geen gegevens over de eigenschappen van de koolstofvezel en het glas die in de plaat worden gebruikt, maar we laten mechanische eigenschapstests uitvoeren op het afgewerkte schuimkernpaneel, waarvan de gegevens binnenkort beschikbaar zouden moeten zijn.

De meeste tests zijn uitgevoerd volgens DIN EN ISO 527-4. De buigeigenschappen zijn getest volgens DIN EN ISO 14125.

Hallo David, zoals je al aangeeft, is het belangrijkste bij het bevestigen op een paneel met kern dat je de kern niet verplettert met een te plaatselijke kracht. Dit kan worden gedaan met behulp van machinaal bewerkte fittingen, zoals een top-hat sectie, of het kan worden gedaan door het schuim te verwijderen en de holte te vullen met vast materiaal (meestal epoxyhars). Ik ben bang dat we geen montagebussen hebben, omdat er te veel variatie is in de benodigde afmetingen (busdiameter, schroefdraadmaat, flensdiameter), indien nodig, deze zouden meestal volgens specificatie worden vervaardigd.

Het verwijderen en volledig opvullen van de kern kan echter zeer effectief zijn en is eenvoudig te doen. Je boort door de binnenste toplaag en verwijdert vervolgens al het resterende kernmateriaal (je kunt zelfs iets breder gaan dan de diameter van het boorgat) en vult vervolgens de holte met een mengsel van epoxyhars. Dit creëert een onpletbaar kerngedeelte dat is verbonden met de binnenkant van de buitenste toplaag (en mogelijk ook met een deel van de binnenkant van de binnenste toplaag). Afhankelijk van waar je het paneel aan bevestigt, kun je een carrosseriering gebruiken om de belasting over de binnenste toplaag te verdelen, een verdeelplaat erop lijmen of het zo laten (vooral als je kern onder de binnenste toplaag hebt kunnen verwijderen).

Wat is het beoogde uiteindelijke gebruik van het paneel?... Als het zoiets is als een splitter, dan kun je rubberen randen rond de voorrand toevoegen, dit is gemakkelijk te doen, geeft een nette afwerking en beschermt het kwetsbare schuim van het paneel.

Als je echt dezelfde geweven koolstofvezelafwerking rond de rand van het paneel wilt laten lopen, dan zou dit ongelooflijk moeilijk zijn en de vrijwel enige manier om dit te doen zou zijn om een gegoten onderdeel te maken, d.w.z. te beginnen met een mal en vervolgens een nieuw onderdeel te lamineren waarbij de koolstofweefsel de contour van de gegoten lip volgt. Een meer realistische 'halve' optie zou zijn om de rand te vullen met een koolstofvuller; dit kan er zeer netjes uitzien, past bij de kleur van de koolstofweefsel en biedt sterkte en bescherming voor de blootgestelde rand. Om dit te doen, zou je ongeveer 3mm van de schuimkern verwijderen, helemaal rondom, en vervolgens een product zoals onze Black Epoxy Repair Filler gebruiken om de 3mm opening te vullen. Zodra het is uitgehard, kun je het vlak maken en polijsten tot een hoogwaardige afwerking.

Elke toplaag op zowel de 6mm als de 11mm panelen is ongeveer 0.5mm dik

Het schuim dat in deze panelen wordt gebruikt, is ons EasyCell 75 gesloten cel PVC-schuim in een dikte van 5mm of 10mm.

De maximale werktemperatuur voor deze plaat is 70°C.

Het schuimkernpaneel is fractioneel stijver dan de 3mm hars geïnfuseerde plaat. Het is ook aanzienlijk lichter in gewicht en gemakkelijker te snijden. De 3mm hars geïnfuseerde plaat is echter, omdat het een massief laminaat is, veel sterker en slagvaster dan het schuimkernpaneel.

Waterstraalsnijden snijdt het schuimkernpaneel gemakkelijk en snel. Zoals met de meeste composieten, kan aanpassing van de waterstraalinstellingen nodig zijn om ervoor te zorgen dat de snede schoon blijft en de rand van de plaat niet afbrokkelt of delamineert.

Ik wil bijvoorbeeld één toplaag uitfrezen en de andere buigen om een hoek van 90 graden te creëren. Omdat de hoofdlast schuifspanning zal zijn, ben ik ook van plan mijn onderdelen onder een hoek van 45 graden ten opzichte van de paneelranden uit te snijden.

Nee, niet rond een bocht van 90 graden. Het probleem zou de koolstofplaat op de buitenste huid zijn, die niet rond een hoek van 90 graden (of zelfs 45 graden) kan worden gebogen zonder een aanzienlijke radius te hebben. Als de bocht rond een kleine radius zou zijn, is de kans groot dat de plaat breekt.

STEL UW EIGEN VRAAG

Productreviews van Klanten Voor Koolstofvezelpaneel met Schuimkern

DIEN UW EIGEN PRODUCTBEOORDELING IN

We publiceren alle beoordelingen van geverifieerde aankopen. Dien uw eigen beoordeling in en help andere klanten met hun keuze.DIEN UW EIGEN PRODUCTBEOORDELING IN

We publiceren alle beoordelingen van geverifieerde aankopen. Dien uw eigen beoordeling in en help andere klanten met hun keuze.Verzendinformatie

Beperkingen

Dit product is niet geclassificeerd als gevaarlijke goederen voor transport en kan zonder beperkingen naar alle bestemmingen worden verzonden.

Verpakkingsgrootte

Er zijn geen beperkingen op de verpakkingsgrootte of toeslagen voor dit product.

Bezorgkosten

Om de bezorgkosten van dit artikel naar uw adres te vinden, voegt u het toe aan uw winkelwagen en gebruikt u vervolgens de directe verzendcalculator op de winkelwagenpagina.

100% VEILIG

BETAALMETHODEN

Easy Composites EU B.V., geregistreerd in Nederland 73601195. Alle inhoud auteursrecht (C) Easy Composites Ltd, 2025. Alle rechten voorbehouden.