Need any help or advice?+44 (0)1782 454499

Downloads (4)

| Safety Datasheet (SDS) - EN | ||

| Technical Datasheet (TDS) | ||

| Fibre Datasheet | ||

| XC110 Processing Guide |

Specification

Fabric Specification

| Fibre Specifics | Toray T300 6k | |

|---|---|---|

| Colour | Black | |

| Fibre Orientation | 0, 90 | |

| Type | Component Prepreg | |

| Resin Matrix | Epoxy | |

| Weave | 2 x 2 Twill | |

| Format | Woven Fabric | |

| Filament Count | 6k | |

| Fibre Type | Carbon Fibre | |

| Brand | XPREG | |

| Ends | 5.1 | cm |

| Picks | 5.1 | cm |

Weight and Dimensions

| Width | 1250 | mm |

|---|---|---|

| Consolidated Thickness | 0.45 | mm |

| Areal Weight | 416 | g/m² |

| Resin Weight | 38 | % |

Fibre Properties

| Min Cure Temp | 85 | °C |

|---|---|---|

| Max Cure Temp | 120 | °C |

| Max Service Temp | 115 | °C |

| Filament Diameter | 7 | µm |

| Out-life (at 20°C) | 30 | Days |

| Freezer-life (at -18°C) | 12 | Months |

| UV Resistance | Good |

Typical Laminate Properties

| Compressive Strength | 483 | MPa |

|---|---|---|

| Tensile Strength | 521 | MPa |

| Tensile Modulus | 55.1 | GPa |

| Flexural Strength | 777 | MPa |

| Flexural Modulus | 46.7 | GPa |

| Interlaminar Shear Strength | 64.7 | MPa |

| Tg Onset (DMA) | 121 | °C |

| Tg Peak (DMA) | 135 | °C |

General Properties

| Gross Weight | 1.22 | kg |

|---|---|---|

| Brand | XPREG |

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Prepreg Product - IMPORTANT!

Uncured prepreg materials are stored at -20°C and are shipped still frozen from our facility. This prepreg has an 'out-life' of at least 30 days at room temperature and so typical delivery times will still leave plenty of safe 'out-life' remaining.

During summer months or periods of hot weather, it is recommended to order prepregs at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Package Size

The packaged size of this product exceeds 1.2m in length and so an additional handling surcharge (charged by the courier) will be included in the quoted shipping cost.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

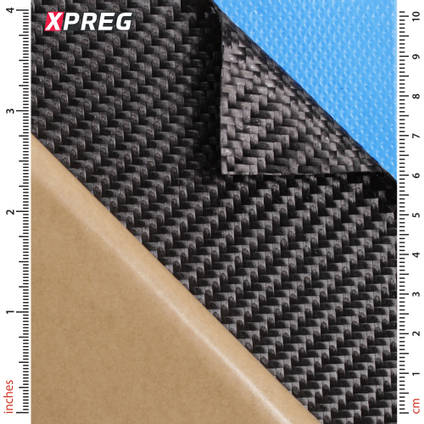

XC110 416g 2x2 Twill 6k Prepreg Carbon Fibre (1250mm)

- XPREG

- XC110-C611T2-416(1250)-1

- No reviews

The backing ply for our XPREG® XC110 out-of-autoclave prepreg carbon fibre system. This is an uncured prepreg material and requires an oven or autoclave to cure it.

This 416gsm 6k prepreg uses a 2x2 twill weave for the classic carbon fibre appearance and excellent drape characteristics. It can be used on its own, in one or more plies, or together with lighter surface ply for the best possible surface finish.

This prepreg reinforcement is 1.25m (1250mm) wide and sold in a choice of prepacked roll lengths.

PRODUCT VERSIONS

Roll Length

AVAILABILITY:19 in stock available for immediate shipping

208 more can built in 2-3 days

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

XPREG® XC110 is an advanced OOA prepreg carbon fibre backing system designed specifically for out-of-autoclave (vacuum bag, oven cure) processing. After several years in development, XC110 is a class-leading prepreg system capable of producing carbon fibre components with a 'class A' surface finish and minimal void content when oven-cured under vacuum pressure only (under optimum conditions, see below).

Components made using the XC110 resin system offer mechanical properties comparable to autoclave-cure systems (such as XPREG® XC130) without the need for expensive autoclave plant or the associated cycle costs. The system is also ideally suited for large components which exceed the capacity of typical autoclaves, such as boat hulls and turbine blades.

XC110 prepregs can be backed-up with (and co-cured alongside) unidirectional reinforcement (from the XC130 range) and are fully compatible with our XA120 adhesive film meaning that even the most complex composite structures - including honeycomb cores - can be achieved out-of-autoclave.

The 416g 6k material listed on this page is recommended for use as an out of autoclave prepreg carbon fibre backing ply, typically used to back-up a layer of XC110 210g 3k Surface Ply. It is however possible to use this large pattern OOA prepreg carbon fibre 6k material as a surface ply, although slightly more surface print should be expected from this heavier fibre.

Typical Uses

OOA prepreg carbon fibre surface fabrics such as this XC110 are the recommended system for both structural and cosmetic applications where components will be cured without an autoclave.

The combination of excellent mechanical performance, visual quality appearance and class-A surface finish make XC110 prepregs suitable for a wide range of applications from large-scale structural components to high-precision cosmetic parts.

High Performance

- Motorsport

- Light Aerospace / RC

- Bike frames

- Racing boats

- Skis, boards

Large Scale

- Boat hulls

- Wind energy

- Mass transit

- Light aircraft

Cosmetic/Lifestyle

- Interior trim

- Phone cases

- Furniture

- Stands/display

How to Buy

All XPREG® prepregs are stored on site in our freezers. To reduce handling time and allow same-day dispatch, prepregs are available in pre-cut roll lengths. Choose the roll length you require from the drop-down list at the top of the page. When ordering a full roll of fabric the drop-down list shows the typical roll length but please allow for length variance of plus or minus 1m which has already been factored into the low unit price of our full length rolls.

Your XPREG® prepreg is sealed in air-tight packaging and will ship from us still frozen. Please see the transport tab for further details and important information about delivery.

The Sample Pack Contains two 400x300mm (15.7x11.8") pieces of pre-preg.

Further Information

Optimum Cure Conditions

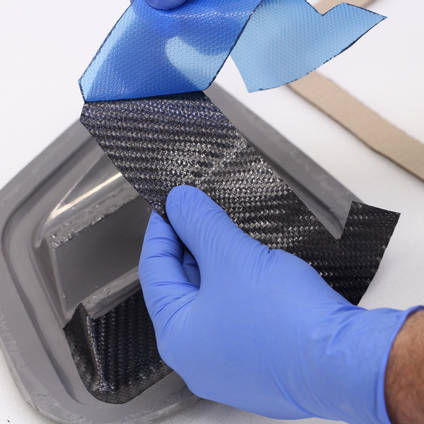

XPREG® XC110 is designed to be oven cured in a vacuum bag at full vacuum pressure, without the need for an autoclave. Used in this way, it can produce parts with a pinhole-free surface finish, under optimum conditions.

The quality of surface finish that can be achieved is determined by several factors, including laminate thickness, bagging technique, vacuum level and cure cycle. For the best chance of a pin-hole free surface finish, ensure:

- Tooling is compatible

- Ply stack does not exceed ~1000gsm total

- Bag is perfectly sealed, vacuum level is 10mbar or better

- Vacuum consumable stack is as recommended

- Multi-stage cure cycle, with final cure temperature of 120°C, is accurately followed

See technical datasheet and XC110 Processing Guide for full recommendations on compatible tooling, laminating technique, vacuum bagging and cure cycles (including lower temperature cure options).

Suitable Moulds/Tooling

Moulds/tools should be epoxy-based composite moulds, epoxy tooling board or metal. In all cases, moulds must be temperature stable to a minimum of 85°C but ideally to 120°C.

Fully Compatible:

- High temp epoxy hand-layup moulds (e.g. EG160 / EMP160)

- Carbon or glass fibre prepreg moulds (e.g. XPREG® XT135)

- Epoxy tooling board (e.g. EB700 Epoxy Tooling Board with S120 Board Sealer)

- Aluminium / stainless steel moulds

- Toughened glass (for flat sheet/panels)

Although it is possible to use vinylester tools (such as Uni-Mould™) they are not recommended due to the increased possibility of surface imperfections (pin holes) which can occur when XPREG® XC110 is cured in the presence of vinylester.

See technical data sheet and XC110 Processing Guide for full details on mould compatibility.

Storage and Handling

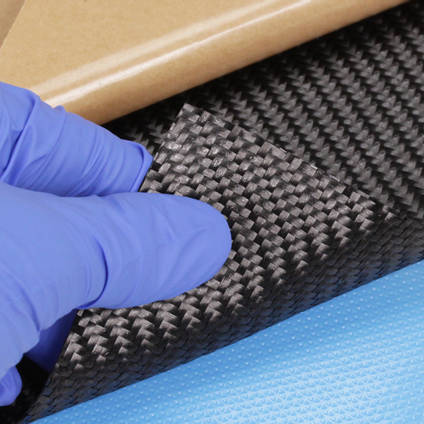

When not in use, XPREG® prepregs should be kept frozen at -18°C (0°F) in sealed plastic packaging. When ready to use, the material should be removed from the freezer and allowed to thaw fully to room temperature before being removed from the packaging.

Remaining material should be re-sealed before returning to the freezer to avoid the risk of moisture uptake.

XPREG® XC110 is an advanced OOA prepreg carbon fibre backing system designed specifically for out-of-autoclave (vacuum bag, oven cure) processing. After several years in development, XC110 is a class-leading prepreg system capable of producing carbon fibre components with a 'class A' surface finish and minimal void content when oven-cured under vacuum pressure only (under optimum conditions, see below).

Components made using the XC110 resin system offer mechanical properties comparable to autoclave-cure systems (such as XPREG® XC130) without the need for expensive autoclave plant or the associated cycle costs. The system is also ideally suited for large components which exceed the capacity of typical autoclaves, such as boat hulls and turbine blades.

XC110 prepregs can be backed-up with (and co-cured alongside) unidirectional reinforcement (from the XC130 range) and are fully compatible with our XA120 adhesive film meaning that even the most complex composite structures - including honeycomb cores - can be achieved out-of-autoclave.

The 416g 6k material listed on this page is recommended for use as an out of autoclave prepreg carbon fibre backing ply, typically used to back-up a layer of XC110 210g 3k Surface Ply. It is however possible to use this large pattern OOA prepreg carbon fibre 6k material as a surface ply, although slightly more surface print should be expected from this heavier fibre.

Typical Uses

OOA prepreg carbon fibre surface fabrics such as this XC110 are the recommended system for both structural and cosmetic applications where components will be cured without an autoclave.

The combination of excellent mechanical performance, visual quality appearance and class-A surface finish make XC110 prepregs suitable for a wide range of applications from large-scale structural components to high-precision cosmetic parts.

High Performance

- Motorsport

- Light Aerospace / RC

- Bike frames

- Racing boats

- Skis, boards

Large Scale

- Boat hulls

- Wind energy

- Mass transit

- Light aircraft

Cosmetic/Lifestyle

- Interior trim

- Phone cases

- Furniture

- Stands/display

How to Buy

All XPREG® prepregs are stored on site in our freezers. To reduce handling time and allow same-day dispatch, prepregs are available in pre-cut roll lengths. Choose the roll length you require from the drop-down list at the top of the page. When ordering a full roll of fabric the drop-down list shows the typical roll length but please allow for length variance of plus or minus 1m which has already been factored into the low unit price of our full length rolls.

Your XPREG® prepreg is sealed in air-tight packaging and will ship from us still frozen. Please see the transport tab for further details and important information about delivery.

The Sample Pack Contains two 400x300mm (15.7x11.8") pieces of pre-preg.

Further Information

Optimum Cure Conditions

XPREG® XC110 is designed to be oven cured in a vacuum bag at full vacuum pressure, without the need for an autoclave. Used in this way, it can produce parts with a pinhole-free surface finish, under optimum conditions.

The quality of surface finish that can be achieved is determined by several factors, including laminate thickness, bagging technique, vacuum level and cure cycle. For the best chance of a pin-hole free surface finish, ensure:

- Tooling is compatible

- Ply stack does not exceed ~1000gsm total

- Bag is perfectly sealed, vacuum level is 10mbar or better

- Vacuum consumable stack is as recommended

- Multi-stage cure cycle, with final cure temperature of 120°C, is accurately followed

See technical datasheet and XC110 Processing Guide for full recommendations on compatible tooling, laminating technique, vacuum bagging and cure cycles (including lower temperature cure options).

Suitable Moulds/Tooling

Moulds/tools should be epoxy-based composite moulds, epoxy tooling board or metal. In all cases, moulds must be temperature stable to a minimum of 85°C but ideally to 120°C.

Fully Compatible:

- High temp epoxy hand-layup moulds (e.g. EG160 / EMP160)

- Carbon or glass fibre prepreg moulds (e.g. XPREG® XT135)

- Epoxy tooling board (e.g. EB700 Epoxy Tooling Board with S120 Board Sealer)

- Aluminium / stainless steel moulds

- Toughened glass (for flat sheet/panels)

Although it is possible to use vinylester tools (such as Uni-Mould™) they are not recommended due to the increased possibility of surface imperfections (pin holes) which can occur when XPREG® XC110 is cured in the presence of vinylester.

See technical data sheet and XC110 Processing Guide for full details on mould compatibility.

Storage and Handling

When not in use, XPREG® prepregs should be kept frozen at -18°C (0°F) in sealed plastic packaging. When ready to use, the material should be removed from the freezer and allowed to thaw fully to room temperature before being removed from the packaging.

Remaining material should be re-sealed before returning to the freezer to avoid the risk of moisture uptake.

Specification

Fabric Specification

| Fibre Specifics | Toray T300 6k | |

|---|---|---|

| Colour | Black | |

| Fibre Orientation | 0, 90 | |

| Type | Component Prepreg | |

| Resin Matrix | Epoxy | |

| Weave | 2 x 2 Twill | |

| Format | Woven Fabric | |

| Filament Count | 6k | |

| Fibre Type | Carbon Fibre | |

| Brand | XPREG | |

| Ends | 5.1 | cm |

| Picks | 5.1 | cm |

Weight and Dimensions

| Width | 1250 | mm |

|---|---|---|

| Consolidated Thickness | 0.45 | mm |

| Areal Weight | 416 | g/m² |

| Resin Weight | 38 | % |

Fibre Properties

| Min Cure Temp | 85 | °C |

|---|---|---|

| Max Cure Temp | 120 | °C |

| Max Service Temp | 115 | °C |

| Filament Diameter | 7 | µm |

| Out-life (at 20°C) | 30 | Days |

| Freezer-life (at -18°C) | 12 | Months |

| UV Resistance | Good |

Typical Laminate Properties

| Compressive Strength | 483 | MPa |

|---|---|---|

| Tensile Strength | 521 | MPa |

| Tensile Modulus | 55.1 | GPa |

| Flexural Strength | 777 | MPa |

| Flexural Modulus | 46.7 | GPa |

| Interlaminar Shear Strength | 64.7 | MPa |

| Tg Onset (DMA) | 121 | °C |

| Tg Peak (DMA) | 135 | °C |

General Properties

| Gross Weight | 1.22 | kg |

|---|---|---|

| Brand | XPREG |

Unfortunately we do not stock any pre-pregs with a flexible resin. The only flexible resin we supply is our EF80 Flexible Epoxy Resin which is suitable for wet lay and vacuum bagged processes.

It is quite common for domestic ovens to only have a lowest settable temperature of around 70C so you're not alone, however, the temperature of the initial 'dwell' is particularly important for OOA (out of autoclave) prepregs and can have quite an effect on the quality of the surface finish on the component so you might need to accept some compromise if you can't accurately keep the initial dwell down to 70C.

Given that the lowest temperature you can set is 76C (when the target would be 70C) I would just suggest using the standard cure cycle (or in your case the standard 'switched' cure cycle, because you can't set a ramp rate) and then leave the rest the same. Technically, you could shorten the initial dwell because you're running a slightly higher temperature, but because the accuracy and stability of a thermostatically switched domestic oven isn't great, you're better off curing a little longer than you need to, to be on the safe side.

This fabric uses a 416gsm base cloth which is then impregnated with resin at a 38% fibre resin ratio to give a total weight of 693g per square meter of finished cloth.

Our XC110 OOA and XC130 Autoclave Component PrePreg and XA120 material don't necessarily need to be shipped in insulated/dry ice packed boxes but is shipped direct from our freezers meaning that for at least the first 12-24hours of the delivery, it remains frozen. We even have several long-term Asia and Australian/NZ based customers who regularly purchase PrePreg from us in large quantities without issues.

The out-life of the material (the cumulative time that the PrePreg can spend out of the freezer) is at least 28 days at 20°C - as such, you should still have a minimum of 20+days of useable life left on arrival. As soon as the material arrives with you, if you put it straight into the freezer, it will preserve the remaining outlife. In most cases the 28 days is conservative too and in practice, you will get more than this.

ASK YOUR OWN QUESTION

Customer Product Reviews for XC110 416g 2x2 Twill 6k Prepreg Carbon Fibre (1250mm)

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Prepreg Product - IMPORTANT!

Uncured prepreg materials are stored at -20°C and are shipped still frozen from our facility. This prepreg has an 'out-life' of at least 30 days at room temperature and so typical delivery times will still leave plenty of safe 'out-life' remaining.

During summer months or periods of hot weather, it is recommended to order prepregs at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Package Size

The packaged size of this product exceeds 1.2m in length and so an additional handling surcharge (charged by the courier) will be included in the quoted shipping cost.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.