Need any help or advice?+44 (0)1782 454499

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

PATTERN MAKING MATERIALS

MATERIALS & CONSUMABLES

CUSTOMER GALLERY

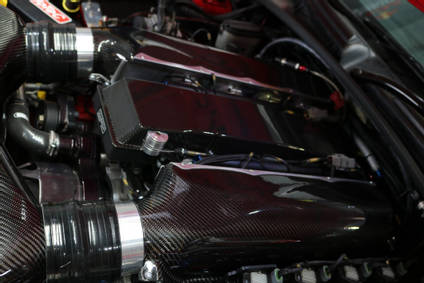

Custom Dual Intake Plenums & Over Radiator Air Filter Housing

This custom dual intake plenums and Over-The-Radiator air filter housing for a GTO Monaro with a 1000hp naturally aspirated LS7 was designed and made by Martin and the team at Unzipped Composites.

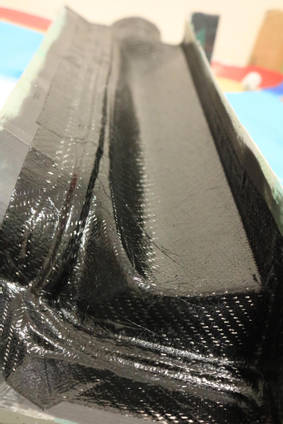

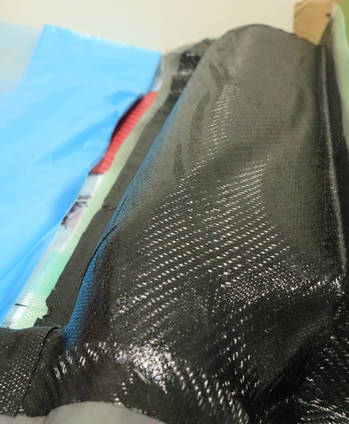

The original base patterns were made using a combination of hand sculpting polyurethane foam using the 2D profile method, utilising existing shapes like aluminium piping and flat bar, and some fibreglassing to blend between the two methods.

Originally the plenums started out being a one piece design, but over a series of iterations were refined to a two piece design with an integrated sealing channel to provide easier installation and to allow the top half of the plenum to be removed for protection whilst working on the engine.

Eventually these base patterns were used to fabricate a quick set of vinylester splash moulds, which were then used to infuse some epoxy/fibreglass patterns

The epoxy patterns were used to construct the final moulds from XT135 tooling Prepreg, which were then polished and sealed before laminating the final components using X-Preg XC110 twill and XC130 unidirectional Prepreg.

Aluminium bosses were machined to self-locate and bolt the two halves together, while the intake mouth was also machined from aluminium and bonded into the bottom plenum half.

The OTR filter housing was made via much the same process, and constructed as a single piece with X-Preg. Special care was taken with the internal dimensions to ensure the filters are a snug interference fit in the filter channel.

ABOUT UNZIPPED COMPOSITES

Unzipped Composites was formed in 2013 by Martin Hanbury.

A motoring enthusiast and keen DIY-er, Martin found that when modifying imports, carbon fibre is something that is quite often required.

After feeling continually dissatisfied with the quality of commercially available carbon fibre components, Martin decided to try his hand at fabricating his own and immediately knew he had found another passion.

In 2014, Martin flew to England to complete one of our Easy Composites 3-day training courses. Since then Unzipped Composites has since had the privilege of working on some of the most high end motorsport builds in Western Australia, with some of the brightest minds the industry has to offer. Being involved with these projects has fast-tracked our experience, and infected us with the drive to provide truly world-class composite solutions.

CONTACT INFORMATION

| Website | www.unzippedcomposites.com |

|---|

| @unzipped_composites |

| www.facebook.com/unzippedcomposites |

| YouTube | www.youtube.com/unzippedcomposites |

|---|

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

PATTERN MAKING MATERIALS

MATERIALS & CONSUMABLES

ABOUT UNZIPPED COMPOSITES

Unzipped Composites was formed in 2013 by Martin Hanbury.

A motoring enthusiast and keen DIY-er, Martin found that when modifying imports, carbon fibre is something that is quite often required.

After feeling continually dissatisfied with the quality of commercially available carbon fibre components, Martin decided to try his hand at fabricating his own and immediately knew he had found another passion.

In 2014, Martin flew to England to complete one of our Easy Composites 3-day training courses. Since then Unzipped Composites has since had the privilege of working on some of the most high end motorsport builds in Western Australia, with some of the brightest minds the industry has to offer. Being involved with these projects has fast-tracked our experience, and infected us with the drive to provide truly world-class composite solutions.

CONTACT INFORMATION

| Website | www.unzippedcomposites.com |

|---|

| @unzipped_composites |

| www.facebook.com/unzippedcomposites |

| YouTube | www.youtube.com/unzippedcomposites |

|---|

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.