Need any help or advice?+44 (0)1782 454499

Specification

General Properties

| Gross Weight | 44.35 | kg |

|---|

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

DS26-P Professional Vacuum Degassing System 26L

- DS-26P-NL

- No reviews

DS26-P is a fully integrated 26L vacuum degassing system fitted with the high capacity EC20 pump. The system is capable of reaching 99% vacuum in around 30 seconds making it ideal for degassing short pot-life resins or for use in fast-turnaround production environments but it is also fully suitable for the degassing of a wide range of materials such as RTV silicone rubber and polyurethane and epoxy casting resins.

Sold as a turn-key system including integrated DVP pump and chamber. 220/240V operation only.

AVAILABILITY:More than 10 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

DS-26P is a 26L vacuum degassing system engineered to offer the highest possible performance and reliability for professional or industrial applications. Its fully integrated design provides a compact footprint, valve-less start/stop operation and extremely fast vacuum pull-down.

Whether you're degassing highly reactive polyurethanes, sensitive water-clear casting resins or a range of RTV silicone rubbers, DC-26P is unmatched for its combination of performance, quality and value.

Please note: The EC20 is NOT suitable for use degassing materials with a high moisture content (such as plaster) or for vacuum drying without the use of a suitable inline moisture trap.

Further Information

Chamber Features & Engineering

The chamber is manufactured from sturdy 4mm mild-steel and finished with a durable grey powder-coating. A clear 20mm acrylic lid provides perfect visibility into the chamber during the degassing operation whilst a custom silicone seal ensures reliable and fast sealing of the chamber.

The lid includes a handle for easy removal and is designed so that it can be hung safely on the back of the chamber during loading and unloading. High quality valves, fittings and a glycerine-filled vacuum gauge complete the chamber and ensure years of trouble-free service.

Superior Performance

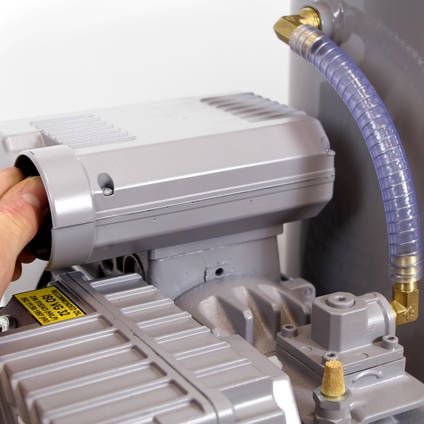

The station is powered by a high-specification EC20 vacuum pump developed in conjuction with leading Italian vacuum pump manufacturer DVP. The pump's optimised vacuum curve and high 12CFM throughput ensure class-leading pull-down times of around 30 seconds to 99% vacuum; essential for fast-curing resins and time saving for all degassing operations.

Connection between the pump and chamber uses large 1/2" BSP hose and fittings throughout, minimising airflow restriction and further improving overall performance.

Zero Oil Mist/Vapour

Unlike oil-bath vacuum pumps the EC20 features continuous gas ballast and exhaust mist eliminator to ensure that the exhausted air is almost entirely free from oil making the pump suitable for sensitive environments such as confined workshops, schools, universities and laboratories.

Ready to Run

The DS-26P is supplied complete with an integrated power switch and IEC socket (with choice of region-suitable power-lead) making installation quick and easy - requiring only a standard domestic wall socket. The system requires minimal assembly and can be up and running in a few minutes. Detailed assembly and daily use instructions are provided.

DC-26P Professional Vacuum Degassing System Assembly and Daily Use Instructions

Which System to Choose?

Alongside this DC-26S Professional degassing system, Easy Composites also offer the DC-26P Starter degassing system, so which system is right for you?

| DC-26P Professional Degassing System | DC-26S Starter Degassing System |

|---|---|

| Listed on this page | Alternative system |

|

|

Spare/Replacement Parts

We can supply any replacement or spare parts required to keep your DC26 Vacuum Degassing Chamber in full working order. The two most likely replacement parts are available to buy online:

Use with Acrylic Resins, Solvented Resins and Solvents

Whilst clear acrylic provides the best combination of clarity, durability and practicality for the vast majority of applications, it is highly susceptible to attack from solvents such as acetone and styrene, and acrylic compounds such as methacrylate ester. This is true for all potential lid materials (such as Plexiglass, Perspex and polycarbonate).

For this reason, the chamber must NOT be used for the degassing of acrylic resins (such as 'Cactus Juice' methacrylate) or styrene-borne resins such as polyesters and vinylesters. Use of the chamber to degas such materials will weaken the integrity of the lid and ultimately result in failure.

It is also essential to never use solvents such as acetone, alcohol or MEK to clean the lid.

Chamber and System Dimensions

| Chamber Internal Dimensions (mm) (H x Diameter) | 350 x 295 |

|---|---|

| Chamber Internal Volume (litres) | 26 |

| Recommended Capacity (litres) | 6 |

| System Overall Dimensions(mm) (L x W x H) | 475 x 632 x 386 |

| System Overall Weight (kg) | 44 |

DVP EC.20 Technical Specification

| Property | Units | 50Hz | 60Hz |

|---|---|---|---|

| Manufacturer | - | DVP | |

| Country of Manufacture | - | Italy | |

| Part Number | - | EC20-1 | |

| Nominal Capacity (Metric) | m³/h | 20 | 24 |

| Nominal Capacity (Imperial) | CFM | 11.77 | 14.13 |

| Total Final Pressure (Abs) | % | 99.95 | 99.95 |

| Motor Power | kW | 0.75 | 0.9 |

| Nominal RPM | n/min | 2800 | 3300 |

| Noise Level (UNI EN ISO 2151 - K - 3db) | dB(A) |

64 | 67 |

| Weight | kg | 19 | 19 |

| Type of Oil (DVP Original) | DVP Part # | BV32 (SW40) | |

| Type of Oil (Compatible) | Easy Comp Part # | VPO32 | |

| Oil Capacity Min / Max | litres | 0.45 / 0.50 | |

| Pump Intake / Outlet Fitting | - | 1/2"G/BSPT | |

| Pump Outlet Fitting | - | 1/2"G/BSPT | |

| Continuous Duty Working Range (Abs) | mbar - hPa | 400 - 2 | |

| Operating Temperature @ 20°C | °C | 60 - 65 | 65 - 70 |

| Required Room Temperature | °C | 12 - 40 | |

| Ambient Temperature for Storage | °C | -20 - 50 | |

| Max Humidity / Altitude | 80% / 1000m s.l.m | ||

DS-26P is a 26L vacuum degassing system engineered to offer the highest possible performance and reliability for professional or industrial applications. Its fully integrated design provides a compact footprint, valve-less start/stop operation and extremely fast vacuum pull-down.

Whether you're degassing highly reactive polyurethanes, sensitive water-clear casting resins or a range of RTV silicone rubbers, DC-26P is unmatched for its combination of performance, quality and value.

Please note: The EC20 is NOT suitable for use degassing materials with a high moisture content (such as plaster) or for vacuum drying without the use of a suitable inline moisture trap.

Further Information

Chamber Features & Engineering

The chamber is manufactured from sturdy 4mm mild-steel and finished with a durable grey powder-coating. A clear 20mm acrylic lid provides perfect visibility into the chamber during the degassing operation whilst a custom silicone seal ensures reliable and fast sealing of the chamber.

The lid includes a handle for easy removal and is designed so that it can be hung safely on the back of the chamber during loading and unloading. High quality valves, fittings and a glycerine-filled vacuum gauge complete the chamber and ensure years of trouble-free service.

Superior Performance

The station is powered by a high-specification EC20 vacuum pump developed in conjuction with leading Italian vacuum pump manufacturer DVP. The pump's optimised vacuum curve and high 12CFM throughput ensure class-leading pull-down times of around 30 seconds to 99% vacuum; essential for fast-curing resins and time saving for all degassing operations.

Connection between the pump and chamber uses large 1/2" BSP hose and fittings throughout, minimising airflow restriction and further improving overall performance.

Zero Oil Mist/Vapour

Unlike oil-bath vacuum pumps the EC20 features continuous gas ballast and exhaust mist eliminator to ensure that the exhausted air is almost entirely free from oil making the pump suitable for sensitive environments such as confined workshops, schools, universities and laboratories.

Ready to Run

The DS-26P is supplied complete with an integrated power switch and IEC socket (with choice of region-suitable power-lead) making installation quick and easy - requiring only a standard domestic wall socket. The system requires minimal assembly and can be up and running in a few minutes. Detailed assembly and daily use instructions are provided.

DC-26P Professional Vacuum Degassing System Assembly and Daily Use Instructions

Which System to Choose?

Alongside this DC-26S Professional degassing system, Easy Composites also offer the DC-26P Starter degassing system, so which system is right for you?

| DC-26P Professional Degassing System | DC-26S Starter Degassing System |

|---|---|

| Listed on this page | Alternative system |

|

|

Spare/Replacement Parts

We can supply any replacement or spare parts required to keep your DC26 Vacuum Degassing Chamber in full working order. The two most likely replacement parts are available to buy online:

Use with Acrylic Resins, Solvented Resins and Solvents

Whilst clear acrylic provides the best combination of clarity, durability and practicality for the vast majority of applications, it is highly susceptible to attack from solvents such as acetone and styrene, and acrylic compounds such as methacrylate ester. This is true for all potential lid materials (such as Plexiglass, Perspex and polycarbonate).

For this reason, the chamber must NOT be used for the degassing of acrylic resins (such as 'Cactus Juice' methacrylate) or styrene-borne resins such as polyesters and vinylesters. Use of the chamber to degas such materials will weaken the integrity of the lid and ultimately result in failure.

It is also essential to never use solvents such as acetone, alcohol or MEK to clean the lid.

Chamber and System Dimensions

| Chamber Internal Dimensions (mm) (H x Diameter) | 350 x 295 |

|---|---|

| Chamber Internal Volume (litres) | 26 |

| Recommended Capacity (litres) | 6 |

| System Overall Dimensions(mm) (L x W x H) | 475 x 632 x 386 |

| System Overall Weight (kg) | 44 |

DVP EC.20 Technical Specification

| Property | Units | 50Hz | 60Hz |

|---|---|---|---|

| Manufacturer | - | DVP | |

| Country of Manufacture | - | Italy | |

| Part Number | - | EC20-1 | |

| Nominal Capacity (Metric) | m³/h | 20 | 24 |

| Nominal Capacity (Imperial) | CFM | 11.77 | 14.13 |

| Total Final Pressure (Abs) | % | 99.95 | 99.95 |

| Motor Power | kW | 0.75 | 0.9 |

| Nominal RPM | n/min | 2800 | 3300 |

| Noise Level (UNI EN ISO 2151 - K - 3db) | dB(A) |

64 | 67 |

| Weight | kg | 19 | 19 |

| Type of Oil (DVP Original) | DVP Part # | BV32 (SW40) | |

| Type of Oil (Compatible) | Easy Comp Part # | VPO32 | |

| Oil Capacity Min / Max | litres | 0.45 / 0.50 | |

| Pump Intake / Outlet Fitting | - | 1/2"G/BSPT | |

| Pump Outlet Fitting | - | 1/2"G/BSPT | |

| Continuous Duty Working Range (Abs) | mbar - hPa | 400 - 2 | |

| Operating Temperature @ 20°C | °C | 60 - 65 | 65 - 70 |

| Required Room Temperature | °C | 12 - 40 | |

| Ambient Temperature for Storage | °C | -20 - 50 | |

| Max Humidity / Altitude | 80% / 1000m s.l.m | ||

Specification

General Properties

| Gross Weight | 44.35 | kg |

|---|

Yes, it could be beneficial and effective to use our Degassing System to remove air trapped in the polyurethane flooring resin you are using. After degassing the mixed resin, it would still be important to avoid entrapping new air during the pouring process but, providing this can be avoided, it's likely that degassing the resin before pouring would improve the results significantly.

At the moment, we only manufacture this one size of degassing chamber which seems to be a good size for most people’s applications. Don’t forget that when you degas a silicone rubber for example it will grow to about 5 times (or more) its original volume and so you need to allow lots of ‘head-room’ inside the chamber to allow for this expansion.

If you’re only degassing a small amount of material then you can add some dead-weight to the chamber (like bricks for example) that can take up as much volume as you desire. Doing this will mean that the pump will empty the chamber much more quickly therefore effectively behaving like a smaller chamber. Therefore, by buying a larger chamber and packing it out in this way it will work like a small chamber but if you ever needed the capacity of a larger chamber in the future then you could just remove the packing, rather than buy another chamber.

ASK YOUR OWN QUESTION

Customer Product Reviews for DS26-P Professional Vacuum Degassing System 26L

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

RELATED PRODUCTS

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.