Need any help or advice?+44 (0)1782 454499

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

CUSTOMER GALLERY

Forged Carbon Brake Lever

Working in a small garage, I, a passionate dirt bike enthusiast, faced a broken brake lever on my Honda CR 125. With Inspiration from EC's video on How to Compression Mould Forged Carbon Fibre Components I was determined to fix the issue, by creating a carbon fibre replacement.

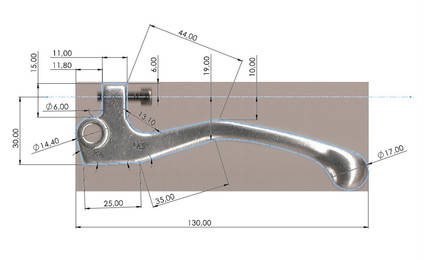

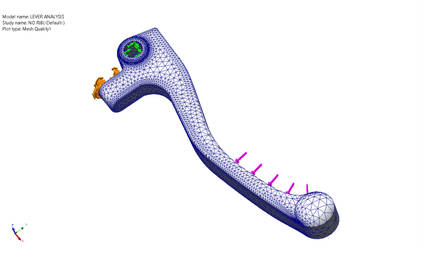

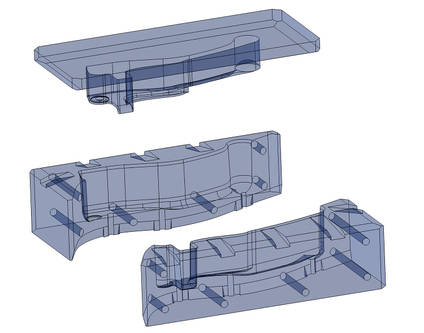

I began by reverse-engineering the original lever and designing a 3D model in CAD. Through Finite Element Analysis (FEA), I optimized the design for increased strength. This design for the brake lever was then used to design a mould. This mould was designed to be used with the forged carbon process.

Using the technology of FDM 3D printing, the mould was printed. Then a mixture of carbon fibre and epoxy was used to fill the mould with the required amount of material. The mould parts were then pressed together and I eagerly awaited the results. However, a small air bubble caused a fault in the lever.

Undeterred, I made a second attempt. Adding extra carbon fibre to problem area eliminated air bubble imperfections. After finishing the surface and fitting the carbon fibre brake lever onto my dirt bike, I can conclude a lever as a really well made.

The process of making was a simple way to create a wide range of complex composite parts. I look forward to make another part for my motorcycle.

A video of the process can be found here: Motorcycle Brake Lever Honda CR125

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.