Need any help or advice?+44 (0)1782 454499

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MOULD MAKING MATERIALS

PATTERN MAKING MATERIALS

COMPONENT MATERIALS

CUSTOMER GALLERY

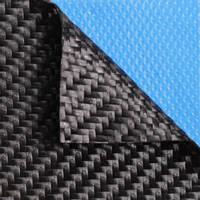

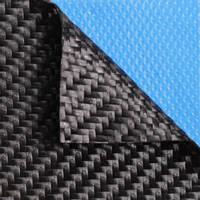

Custom Carbon Fibre Hand bag

Nick was always keen to try epoxy and carbon fibre and went on a short course in 2005 but didn't take it any further until about three years ago when he was introduced to Easy Composites. The idea for a handbag came from seeing one in an airport boutique and he chose to base his design on a bag which his wife already had (also in some of the photos).

There are three patterns for the bag, the main body, the handle and the loops to attach the handle. Nick used MDF as the core material and initially used XCR coating resin to seal and subsequently polish the patterns. Since he was learning as he went along, he found the PCG Pattern Coat to be much better suited to the application due to the shorter cure time.

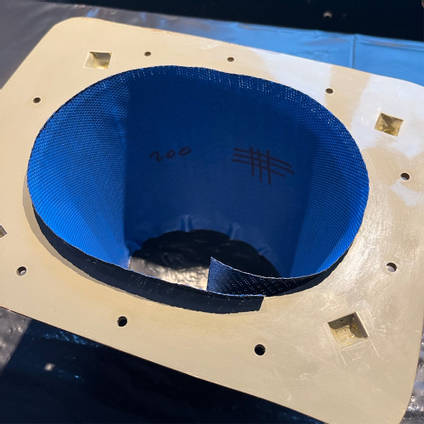

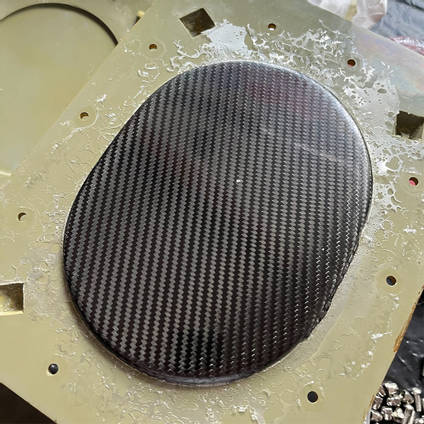

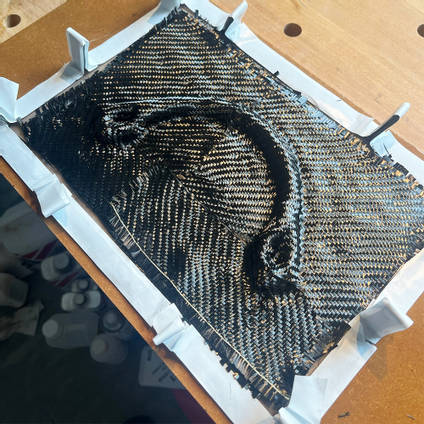

Nick decided from the outset that he wanted to use XC110 Prepreg for the finished parts as he had some previous experience with prepregs and he therefore chose EG160 Gel Coat and EL160 Epoxy Resin as the system to use to take moulds from the patterns. The early patterns were made using a wet layup by hand, which worked well but had some dry areas due to the resin running out during the cure.

Having experimented with a few patterns for the handle and the loop, Nick settled on a new process of resin infusion, also using the EL160 resin which was pretty successful but required some re-work with EG160 where some bridging occurred. All the moulds were prepared with S120 Board Sealer and CR1 Easy-Lease Release Agent which worked very well and Nick was very pleased with all the parts releasing straight from the moulds.

The silk liner was sewn onto a strip of carbon fibre veneer sheet and then bonded into the body of the bag with ET5429 adhesive. All parts were finished with a clear coat to give a hi-gloss finish and the handle loops were attached using ET5429. After some progress with finished parts, Nick decided to carry on and make a total of three bags and he is pretty satisfied with the results.

ABOUT NICK WILSON

Nick started having a go with composites as a teenager making skateboard decks and he carried on through the 1980s with three windsurfing boards which were all GRP. In the late 1990s he made a half scale Austin Healey Sprite for my children (also GRP).

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MOULD MAKING MATERIALS

PATTERN MAKING MATERIALS

COMPONENT MATERIALS

ABOUT NICK WILSON

Nick started having a go with composites as a teenager making skateboard decks and he carried on through the 1980s with three windsurfing boards which were all GRP. In the late 1990s he made a half scale Austin Healey Sprite for my children (also GRP).

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.